OVERVIEW

NRSs (sesmic) Series - Ultra rigid multi compartment racks for high density application in data centers & server rooms specially designed for seismic zone. The seismic rack manufactured out of steel sheet, punched, formed, welded and Powder coated with highest quality standards under stringent ISO 9001 | ISO 14001 | ISO 27001 | ISO 45001 Manufacturing & Quality management system to ensure highest quality product.

Standard for racks configuration will be welded to ultra-rigid frame with 4 no pillars of 14 Gauge steel sheet 5 folded profile welded to top and bottom ribbed/ reinforced frame additionally supported depth wise by welding 6 no depth rail 4 folded 75mm 14 Gauge profile & diagonally reinforced by 4 no of 4 folded 50mm 14 gauge profile. Associated with vented top cover with fan mounting provision Front Glass or perforated Metal Door with Lock & Key and Back Vented / Perforated Metal Door with Lock & key and partially vented or Plain side panels 1200 deep rack will be configured with dual side panel. Braced to floor/ raised floor with bracing bolts and additionally braced on top by runway to rigid wall OR Pillar.

Available in 42RU ~ 47RU Variants with 650, 800, 1000 & 1200 Depth configurations 600 & 800 Width configurations.

Technical Specification

| Technical Data: | |

|---|---|

| Basic Frame | Steel Folded |

| Construction | Welded |

| Top & Bottom Cover | Welded to Frame with Cable entry exit cut outs |

| Front Door | Lockable Perforated steel Door Plain /Vented |

| Rear Door | Lockable Perforated steel Door Plain /Vented |

| 19” Mounting Angle | Formed Steel |

| Standard Finish | Powder coated |

| Standard Colour | Grey & Off White OR Black |

| Standard Mounting | Braced to Floor/ Raised Floor Bracing Bolts |

| Rack Standard | Conforms to DIN 41494 or equivalent standard |

| Static Load | 1500 Kg |

| Seismic Load | 750 Kg |

Note:

- Other Colour Powder Coating, Etsi Std. Racks and other Models can be manufactured on Request.

| Model Matrix & Dimensions | |||||||

|---|---|---|---|---|---|---|---|

| NRSs Series | H | h | W | w | D | d | Plinth |

| 42U 600X650 | 2010 | 42U | 600 | 19” | 650 | 550 | |

| 42U 600X800 | 2010 | 42U | 600 | 19” | 800 | 700 | |

| 42U 600X1000 | 2010 | 42U | 600 | 19” | 1000 | 900 | |

| 42U 600X1200 | 2010 | 42U | 600 | 19” | 1200 | 1100 | |

| 44U 600X650 | 2099 | 44U | 600 | 19” | 650 | 550 | |

| 44U 600X800 | 2099 | 44U | 600 | 19” | 800 | 700 | |

| 44U 600X1000 | 2099 | 44U | 600 | 19” | 1000 | 900 | |

| 44U 600X1200 | 2099 | 44U | 600 | 19” | 1200 | 1100 | |

| 45U 600X650 | 2143 | 45U | 600 | 19” | 650 | 550 | |

| 45U 600X800 | 2143 | 45U | 600 | 19” | 800 | 700 | |

| 45U 600X1000 | 2143 | 45U | 600 | 19” | 1000 | 900 | |

| 45U 600X1200 | 2143 | 45U | 600 | 19” | 1200 | 1100 | |

| 47U 600X650 | 2232 | 47U | 600 | 19” | 650 | 550 | Integrated to Frame |

| 47U 600X800 | 2232 | 47U | 600 | 19” | 800 | 700 | |

| 47U 600X1000 | 2232 | 47U | 600 | 19” | 1000 | 900 | |

| 47U 600X1200 | 2232 | 47U | 600 | 19” | 1200 | 1100 | |

| 42U 800X800 | 2010 | 42U | 800 | 19”/27” | 800 | 700 | |

| 42U 800X1000 | 2010 | 42U | 800 | 19”/27” | 1000 | 900 | |

| 42U 800X1200 | 2010 | 42U | 800 | 19”/27” | 1200 | 1100 | |

| 44U 800X800 | 2099 | 42U | 800 | 19”/27” | 800 | 700 | |

| 44U 800X1000 | 2099 | 42U | 800 | 19”/27” | 1000 | 900 | |

| 44U 800X1200 | 2099 | 42U | 800 | 19”/27” | 1200 | 1100 | |

| 45U 800X800 | 2248 | 45U | 800 | 19”/27” | 800 | 700 | |

| 45U 800X1000 | 2248 | 45U | 800 | 19”/27” | 1000 | 900 | |

| 45U 800X1200 | 2248 | 45U | 800 | 19”/27” | 1200 | 1100 | |

| 47U 800X800 | 2337 | 47U | 800 | 19”/27” | 800 | 700 | |

| 47U 800X1000 | 2337 | 47U | 800 | 19”/27” | 1000 | 900 | |

| 47U 800X1200 | 2337 | 47U | 800 | 19”/27” | 1200 | 1100 | |

Features & Accessories

Features

- UL Certified

- Conforms to DIN 41494 or equivalent EIA / ISO / EN standard

- Designed to NEBS™ Zone 4 via Telecordia GR-63-CORE

- Adjustable mounting depth

- 4 No Adjustable, 19” verticals with punched 9mm Square Hole and Universal 12.7mm-15.875mm-15.875mm alternating hole pattern offers greater mounting flexibility, maximizes usable mounting space

- Numbered U positions,

- Universal 25MM Pitch Holes For ETSI Standard Racks

- State-of-the-art manufacturing methods provide the best product quality and fastest delivery in the industry

- 100% assured compatibility with all equipments conforming to DIN 41494 (General industrial standard for equipments)

- Powder coated finish with Seven tank pretreatment process meeting IS

- Grounding & Bonding Options

- Earthing continuity Kit

- 2 or 4 Fan module Mount Provision on top cover

Note

- A Telcordia GR-63-CORE compliant test can be conducted by recognised independent laboratory. This test is conducted on an installation-specific basis with customer - installed equipment and cabling mounted inside.

Abbreviations

- Overall Height = Frame Height+Plinth

- Other models can be manufactured on request

- It is recommended to distribute the Load along with U space in the Rack

- Dimension are in MM

Note:

- Overall Height = Frame Height+Plinth

- Other models can be manufactured on request

- It is recommended to distribute the Load along with U space in the Rack

- Dimension are in MM

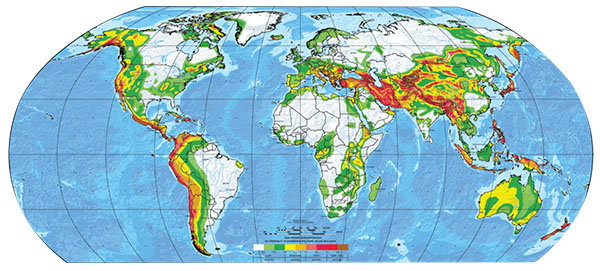

What is Seismic Zones?

Seismic Rack standards are often specified in terms of the earthquake risk zones. Zones vary from 0 to 4, 0 Zone designating no substantial risk, zones 3 and 4 are generally the regions where Seismic Racks are Required

Seismic Zones

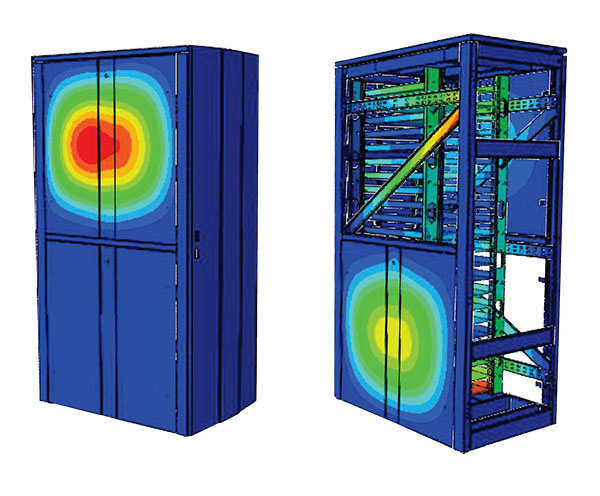

What is Seismic Rack?

Manufacturing the Rack & Enclosures understanding above Seismic Zone requirements and designing through FEA ( Finite Element analysis. According to Telcordia (formerly Bellcore) GR-63-CORE Network Equipment Building System (NEBS) requirements for physical protection.

Displacement Distribution

We're Here to Help

Our team of experts is ready to helping you find the perfect rack solution

tailored to your specific needs.